Bending strength, МPa – from 23 to 17

Swelling in thickness per 24 hours, % – from 35 to 8

Density, кg/m3 – from 650 to 900

Humidity, % - from 4 to 11

15-115070-120

The background is white

14-50009-119

The background Is platinum

15-115070-120

The background is vanilla

14-90032-132

The background is red

14-10137-003

Belfort Oak

14-05006-144

Mountain Alder

14-22012-110

Italian Walnut

14-20072-118

Donskoy Nut

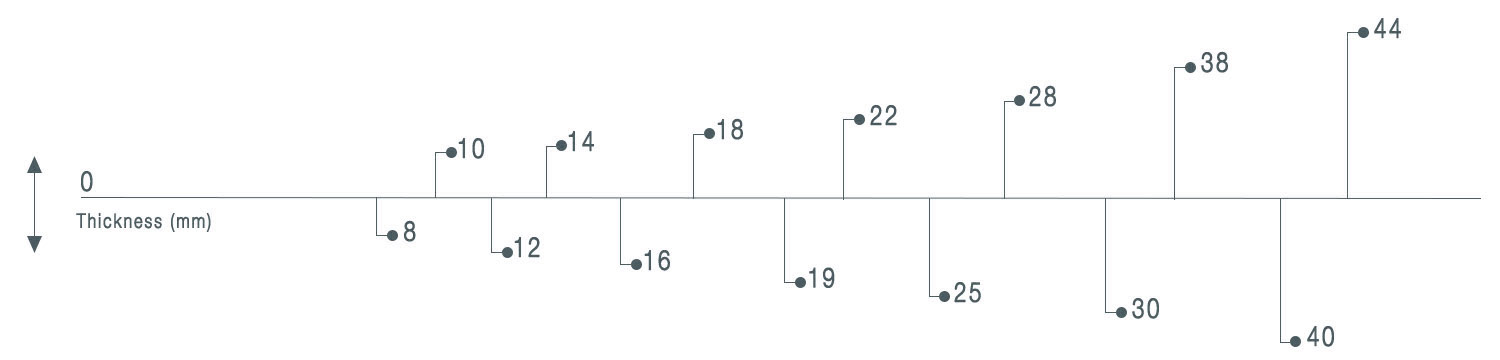

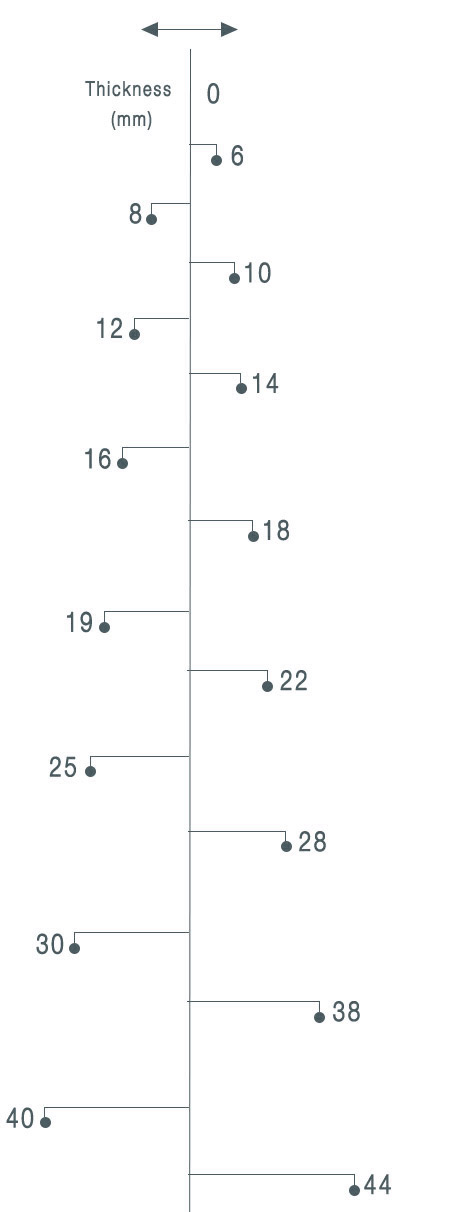

Physical and mechanical indicators of MDF.H:

Density, kg/m3 650÷900

Humidity, % 4÷11

Swelling in thickness per 24 hours, %

The norm for plates with a thickness of, mm:

>9-12 mm % no more 10

>12-19 mm % no more 8

>19-30 mm % no more 7

Transverse tensile strength, MPa, not less

The norm for plates with a thickness of, mm:

>9-12 mm % not less 0,80

>12-19 mm % not less 0,75

>19-30 mm % not less 0,75

Bending strength, Mpa, not less

The norm for plates with a thickness of, mm:

>9-12 mm % not less 26

>12-19 mm % not less 24

>19-30 mm % not less 22

Thickness swelling after cyclic test, %

The norm for plates with a thickness of, mm:

>9-12 mm – 16 %

>12-19 mm – 15 %

>19-30 mm – 15 %

Transverse tensile strength, MPa, not less

The norm for plates with a thickness of, mm:

>9-12 mm % not less 0,25

>12-19 mm % not less 0,20

>19-30 mm % not less 0,15

Roughness, mkm 16÷32

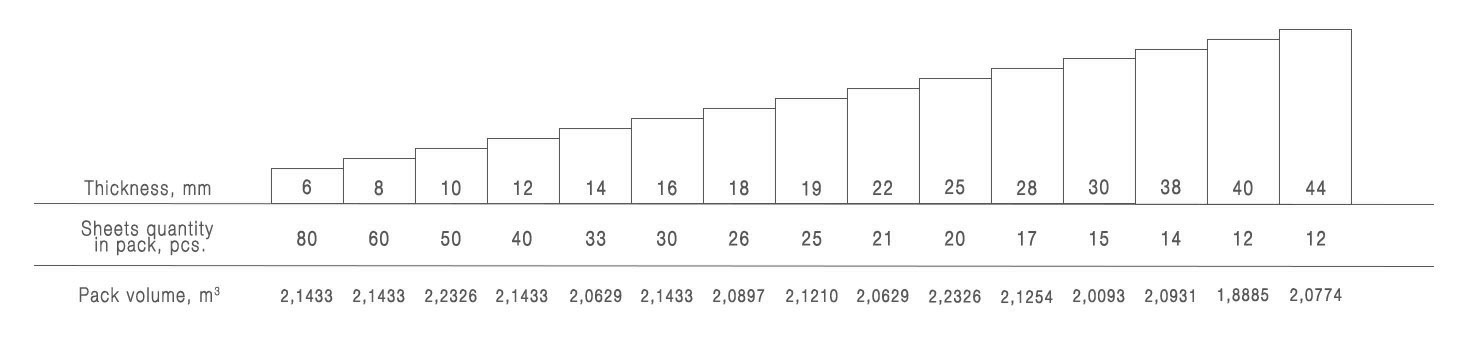

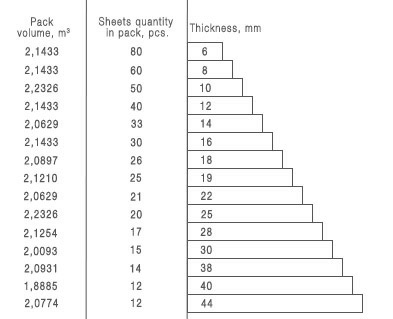

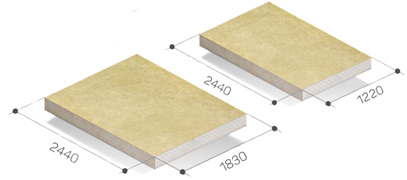

Plate format (2440х1830, 2440х1220)

Moisture-resistant MDF, unlike conventional, has a denser structure. As a result, the plate is not subjected to swelling, and its surface is not destroyed by the action of condensate.

They are recommended for the manufacture of kitchen countertops, door panels, window sills, bathroom furniture, floor bases (including varnishing), finishing of damp and unheated rooms

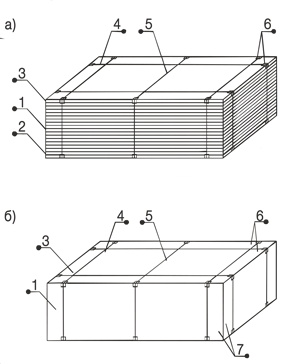

The formed package of plates is pulled together by a polypropylene tape.

At the corners of the foot under the polypropylene tape are placed metal corners according to the packing scheme.

Designations